The founders launched Ss Brewtech with a very clear goal to advance brewing equipment design, performance, and quality to the very highest standards in the industry. With a team that draws upon very strong functional backgrounds in brewing science, mechanical engineering, industrial design, supply chain, logistics, manufacturing, and quality, Ss Brewtech has the people and skillsets you would want and expect from your supplier of pro brewing equipment.

The founders launched Ss Brewtech with a very clear goal to advance brewing equipment design, performance, and quality to the very highest standards in the industry. With a team that draws upon very strong functional backgrounds in brewing science, mechanical engineering, industrial design, supply chain, logistics, manufacturing, and quality, Ss Brewtech has the people and skillsets you would want and expect from your supplier of pro brewing equipment.

Pricing listed is for standard 2 Vessel configuration. Optional Whirlpool vessel is available at additional cost.

Pricing listed is for standard 2 Vessel configuration. Optional Whirlpool vessel is available at additional cost.

A brewhouse is the beating heart of every craft brewery, and a burgeoning brewing operation can’t survive with a single day of downtime related to equipment failures. Furthermore, with more advanced cellaring techniques, sanitation-related stumbling blocks can carry a lasting effect on a brewery’s reputation. We have sought to overcome these surprisingly common problems by demanding that our equipment be built to the highest standards, tolerances, and specifications.

Certified 304 stainless steel and rigorous multi-point inspection throughout the construction of our pro brewhouse ensure your brewhouse will last for years to come.

A brewhouse is the beating heart of every craft brewery, and a burgeoning brewing operation can’t survive with a single day of downtime related to equipment failures. Furthermore, with more advanced cellaring techniques, sanitation-related stumbling blocks can carry a lasting effect on a brewery’s reputation. We have sought to overcome these surprisingly common problems by demanding that our equipment be built to the highest standards, tolerances, and specifications.

Certified 304 stainless steel and rigorous multi-point inspection throughout the construction of our pro brewhouse ensure your brewhouse will last for years to come.

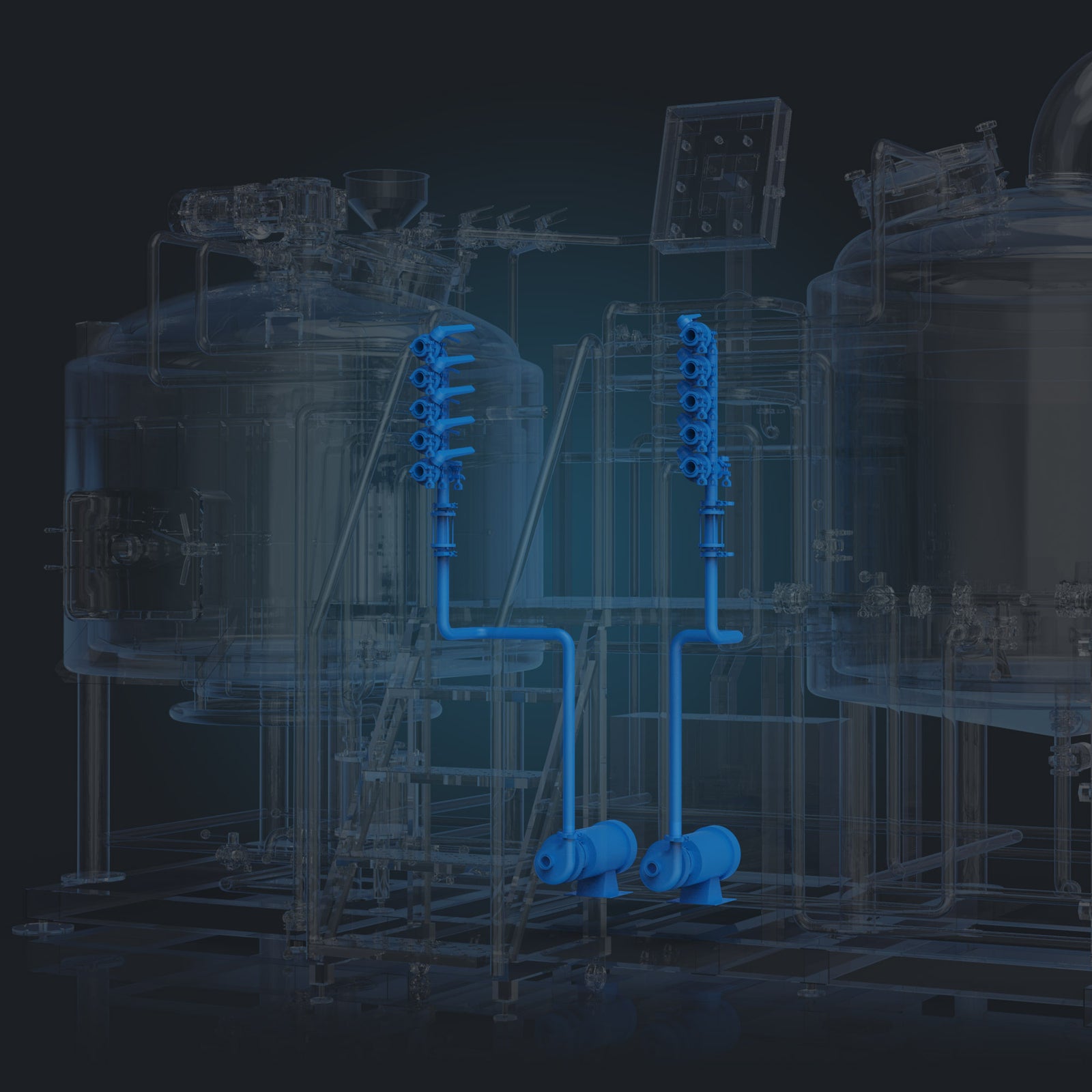

The signature and patented design element of our brewhouses is, without a doubt the consolidated valve tree mounted atop the working platform within easy reach of the main control panel. Laser-etched stainless steel butterfly valves allow for precise flow modulation and control without having to continually move up and down the work platform during the brew day. The attention to detail regarding how brewers work enhances both ease of use and safety.

The signature and patented design element of our brewhouses is, without a doubt the consolidated valve tree mounted atop the working platform within easy reach of the main control panel. Laser-etched stainless steel butterfly valves allow for precise flow modulation and control without having to continually move up and down the work platform during the brew day. The attention to detail regarding how brewers work enhances both ease of use and safety.

The Dual Pump Architecture designed into every Pro Ss Brewhouse provides a level of flexibility simply not available on single pump systems. On 2 vessel brewhouses, the pumps are connected to independent 5 port manifolds, while on the 3V brewhouses, 6 port manifolds are direct the flow to all 3 vessels. The pair of manifolds together form our patented Valve Tree, the signature design element of all Ss Brewhouses.

The upgrade to Ampco pumps provides a reliable foundation for the piping system of the 2020 Ss Pro Brewhouses.

The Dual Pump Architecture designed into every Pro Ss Brewhouse provides a level of flexibility simply not available on single pump systems. On 2 vessel brewhouses, the pumps are connected to independent 5 port manifolds, while on the 3V brewhouses, 6 port manifolds are direct the flow to all 3 vessels. The pair of manifolds together form our patented Valve Tree, the signature design element of all Ss Brewhouses.

The upgrade to Ampco pumps provides a reliable foundation for the piping system of the 2020 Ss Pro Brewhouses.

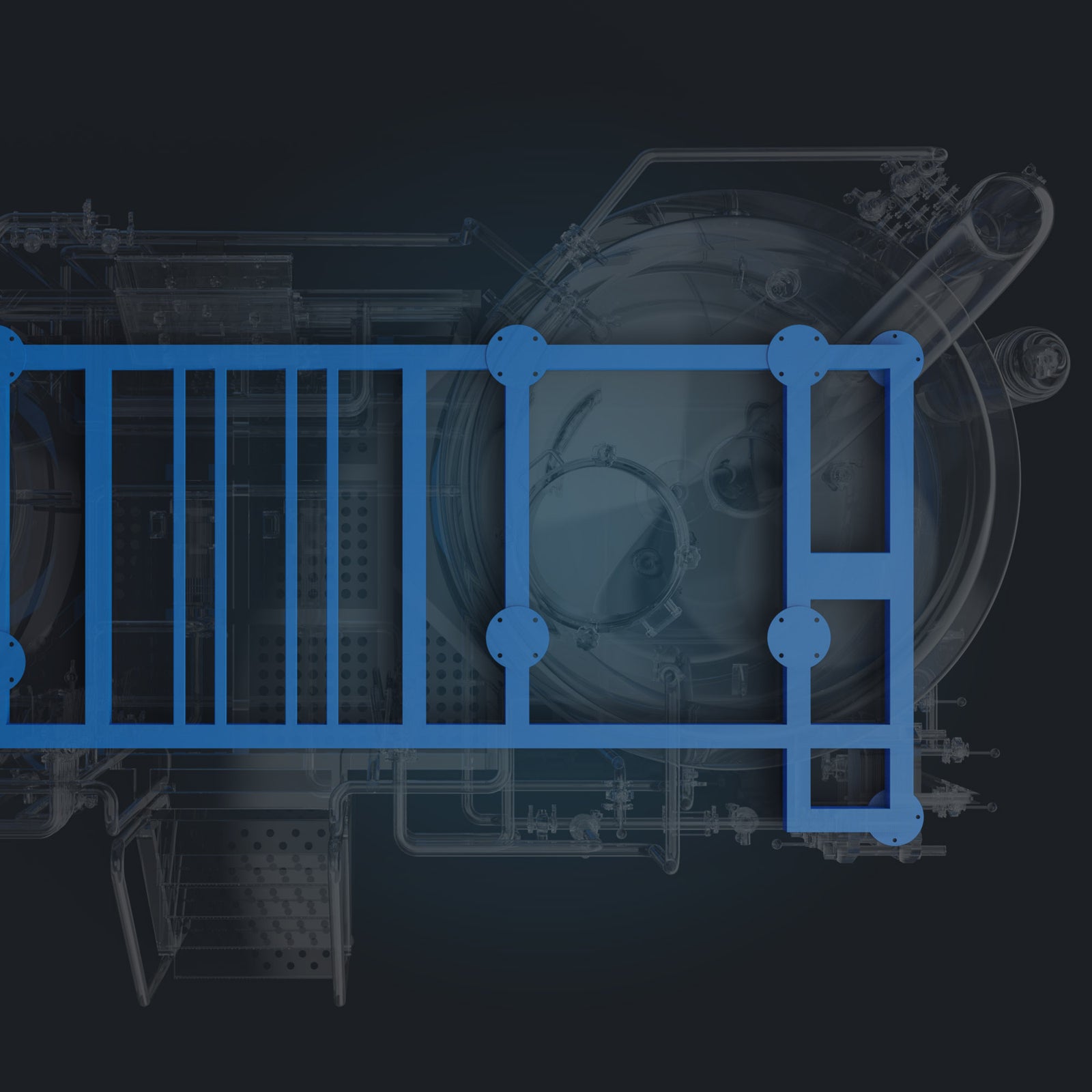

A brewhouse is only as strong as it's foundation, that's why all Ss Brewtech Pro Brewhouses are built on a 3in square stainless steel Uni-Frame. Freestanding vessels have a propensity to leak over time due to torsion stress on the system's piping. The Uni-Frame holds all pipes and vessels with exacting tolerance, virtually eliminating the risk of a system leak.

Additionally, having the brewhouse frame-mounted means most 2 vessel systems ship 100% assembled and require only utilities to be up and running. It's not uncommon for new brewers to brew their first batch within 24 hours of receiving their brewhouse.

A brewhouse is only as strong as it's foundation, that's why all Ss Brewtech Pro Brewhouses are built on a 3in square stainless steel Uni-Frame. Freestanding vessels have a propensity to leak over time due to torsion stress on the system's piping. The Uni-Frame holds all pipes and vessels with exacting tolerance, virtually eliminating the risk of a system leak.

Additionally, having the brewhouse frame-mounted means most 2 vessel systems ship 100% assembled and require only utilities to be up and running. It's not uncommon for new brewers to brew their first batch within 24 hours of receiving their brewhouse.

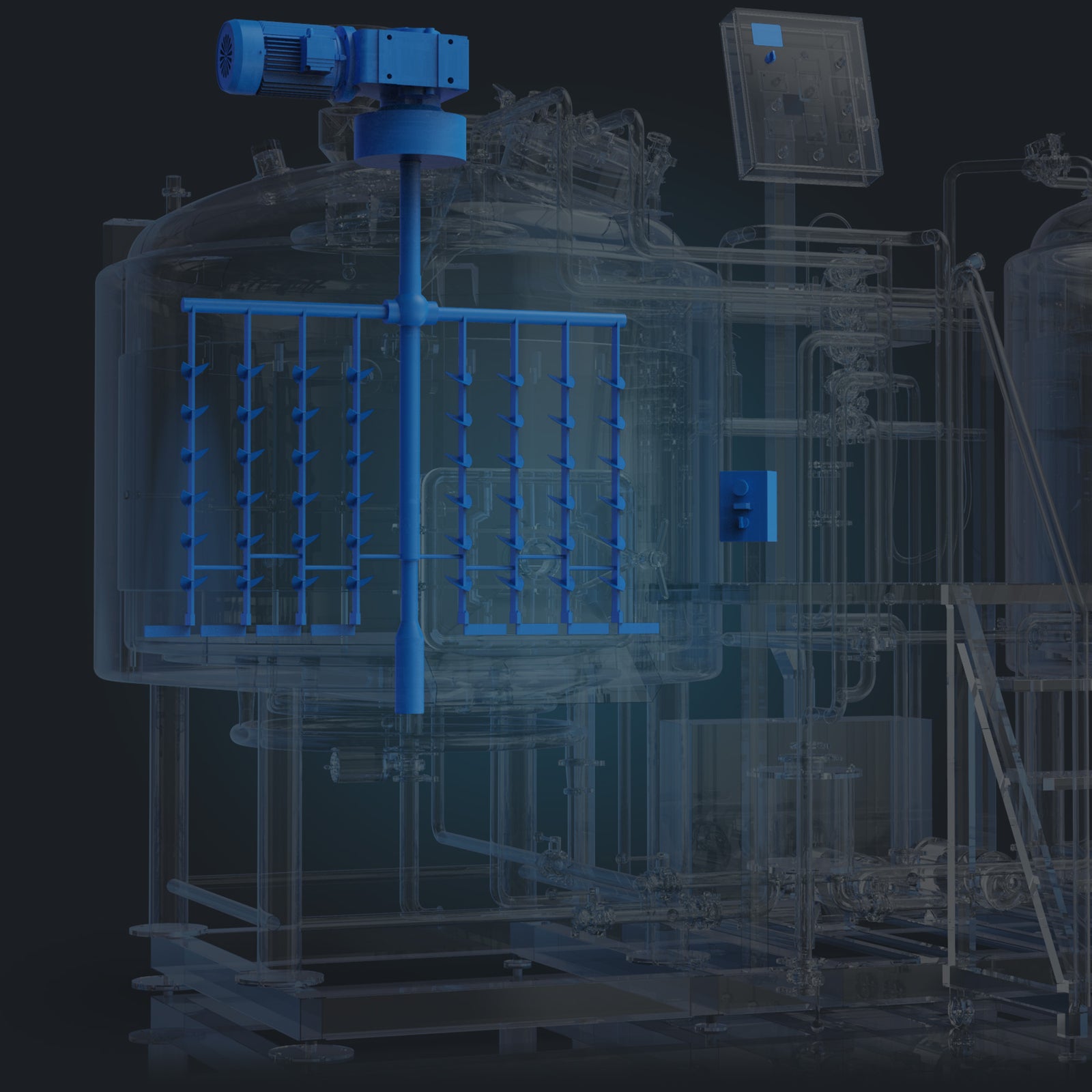

Arguably the most labor-intensive part of any brew day is graining out. Since all 5 bbl and larger Pro Ss Brewhouses come equipped with a mash rake to reduce striations in your mash, we decided to design a series of grain-out paddles into the rake. When the powerful Eurodrive rake motor is switched into reverse, the paddles automatically lock into place and push the grain out of the open door. Through this process, it is possible to remove nearly all spent grain from the mash tun without the need for manual labor.

For the 2020 brewhouses, we've added a remote control box off the platform next to the grain-out door. This addition allows a single operator to grain out with a new level of ease and safety.

Arguably the most labor-intensive part of any brew day is graining out. Since all 5 bbl and larger Pro Ss Brewhouses come equipped with a mash rake to reduce striations in your mash, we decided to design a series of grain-out paddles into the rake. When the powerful Eurodrive rake motor is switched into reverse, the paddles automatically lock into place and push the grain out of the open door. Through this process, it is possible to remove nearly all spent grain from the mash tun without the need for manual labor.

For the 2020 brewhouses, we've added a remote control box off the platform next to the grain-out door. This addition allows a single operator to grain out with a new level of ease and safety.

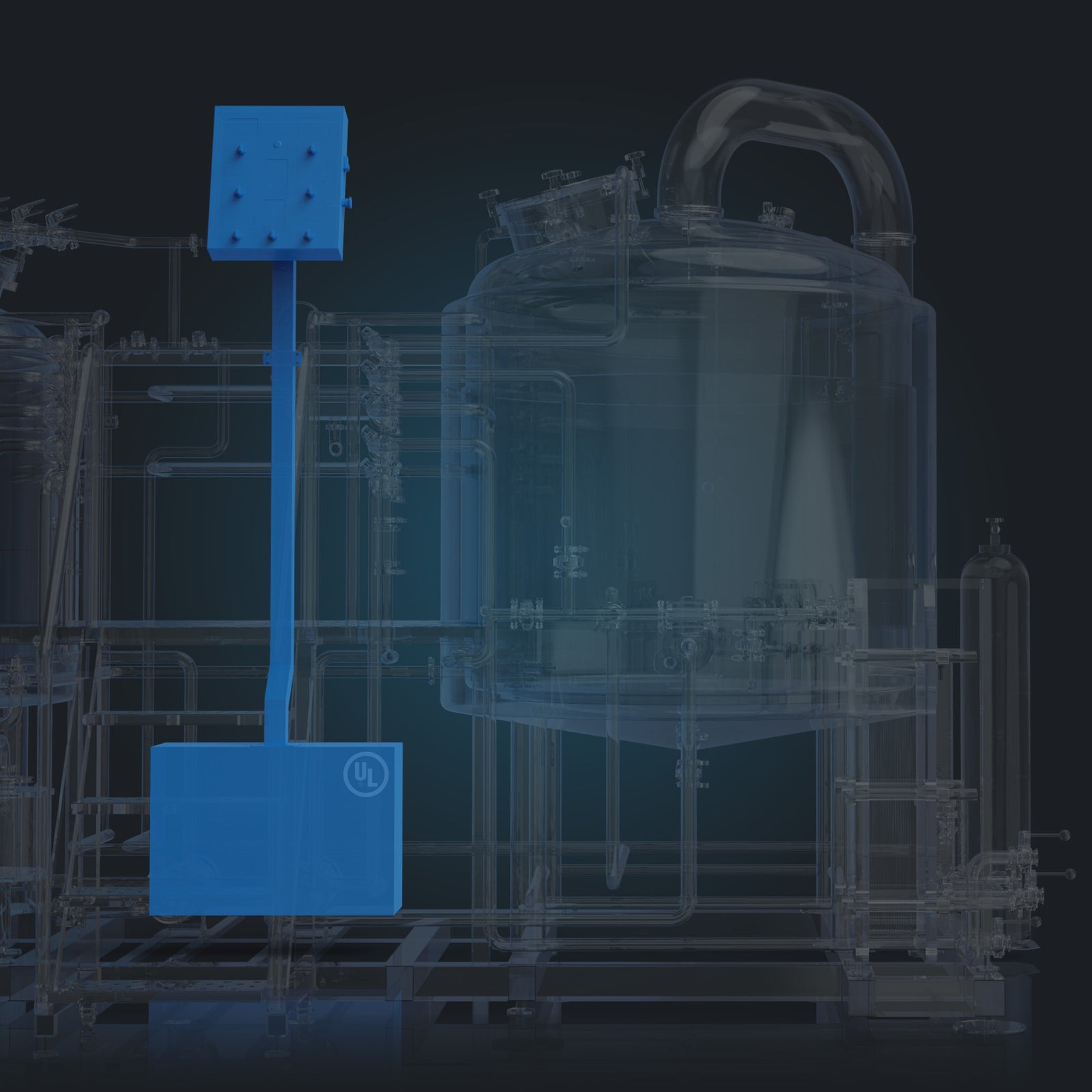

Ss Brewtech's California based production facility is now a UL certified 508a panel shop. UL is the industry standard for safety and quality in industrial electronics. Beyond a breweries own peace of mind knowing their brewhouse is built from the highest quality components.

A UL 508A Listing Mark on an industrial control panel provides evidence of third party certification to the municipal inspection authority and to the purchaser of the panel. UL certification is a requirement in many counties across the country.

Ss Brewtech's California based production facility is now a UL certified 508a panel shop. UL is the industry standard for safety and quality in industrial electronics. Beyond a breweries own peace of mind knowing their brewhouse is built from the highest quality components.

A UL 508A Listing Mark on an industrial control panel provides evidence of third party certification to the municipal inspection authority and to the purchaser of the panel. UL certification is a requirement in many counties across the country.

With the ever-evolving landscape of craft beer, batch size flexibility has become a focus on many successful breweries. The integrated whirlpool option allows efficient single day double batching.

By transferring the wort out of the boil kettle, brewers can immediately begin to run off the second batch , all while knockout takes place from the whirlpool vessel. As a result, a typical 10 bbl double batch (20bbl of wort) can be brewed in an 8 hour day.

With the ever-evolving landscape of craft beer, batch size flexibility has become a focus on many successful breweries. The integrated whirlpool option allows efficient single day double batching.

By transferring the wort out of the boil kettle, brewers can immediately begin to run off the second batch , all while knockout takes place from the whirlpool vessel. As a result, a typical 10 bbl double batch (20bbl of wort) can be brewed in an 8 hour day.

Purchasing a brewhouse is one of the most crucial purchases when starting or expanding your brewery. The entire Ss team, from engineers and designers to brewers and the technical team, are here to help you along the way. The best way to get started is to fill out the short request a quote form at the link below. However, if you have a direct question you'd like to ask the team, feel free to email us at Pro@SsBrewtech.com.

Happy Brewing — The Ss Brewtech Team

Purchasing a brewhouse is one of the most crucial purchases when starting or expanding your brewery. The entire Ss team, from engineers and designers to brewers and the technical team, are here to help you along the way. The best way to get started is to fill out the short request a quote form at the link below. However, if you have a direct question you'd like to ask the team, feel free to email us at Pro@SsBrewtech.com.

Happy Brewing — The Ss Brewtech Team

We are excited to announce the strategic collaboration between Deutsche Beverage + Process and Ss Brewtech, marked by the launch of the "Powered by Deutsche" partnership. This initiative seeks to integrate Deutsche's robust strengths in customer service, technical support and technology with Ss Brewtech's Pro line, featuring 5-20 barrel brewing systems. Both companies have had an established bond as fellow Middleby brands and are now working closer together to provide a more unified solution to the craft brewing community.

Deutsche Beverage + Process, known for custom equipment, and a customer-centric approach brings expertise in providing specialized equipment solutions for Craft Beer, Craft Spirits, RTDs, Coffee, Cannabis, and more. Deutsche's commitment to excellence is reflected in its dedicated customer base and proven systems that consistently generate award-winning products.

In joining Ss Brewtech's innovative Pro Line with Deutsche Beverage + Process's exceptional customer service and technical expertise, we've crafted a partnership that stands out in the industry. Since 2013, Ss Brewtech has pioneered advancements in home brewing equipment, with the Pro Line designed to scale these innovations for commercial production. Coupled with Deutsche's proven customer support, “Powered by Deutsche” is setting new industry benchmarks for efficiency, reliability, and customer experience.

We are excited to announce the strategic collaboration between Deutsche Beverage + Process and Ss Brewtech, marked by the launch of the "Powered by Deutsche" partnership. This initiative seeks to integrate Deutsche's robust strengths in customer service, technical support and technology with Ss Brewtech's Pro line, featuring 5-20 barrel brewing systems. Both companies have had an established bond as fellow Middleby brands and are now working closer together to provide a more unified solution to the craft brewing community.

Deutsche Beverage + Process, known for custom equipment, and a customer-centric approach brings expertise in providing specialized equipment solutions for Craft Beer, Craft Spirits, RTDs, Coffee, Cannabis, and more. Deutsche's commitment to excellence is reflected in its dedicated customer base and proven systems that consistently generate award-winning products.

In joining Ss Brewtech's innovative Pro Line with Deutsche Beverage + Process's exceptional customer service and technical expertise, we've crafted a partnership that stands out in the industry. Since 2013, Ss Brewtech has pioneered advancements in home brewing equipment, with the Pro Line designed to scale these innovations for commercial production. Coupled with Deutsche's proven customer support, “Powered by Deutsche” is setting new industry benchmarks for efficiency, reliability, and customer experience.