We aren't ready to show it off quite yet but we've been working on a new evolution of our eBrewing line. Using tech developed for SVBS and designed with today's homebrewer in mind, eBrewing 2.0 will bring exciting changes to our electric line up.

Featuring modular controllers that allow you to scale your system up or down easily, easy-to-use touch screen controls, and Brew in A Basket systems for compact footprints, eBrewing 2.0 will bring a lot to the table...or Brew Cube.

In the meantime, we are discounting our first generation of eBrewing gear to help make some room in the warehouse. eKettles, eControllers, RIMS, Systems, and eBrewing Accessories are marked down 30%. eBrewing Kits are discounted to reflect the same savings available on individual eBrewing products.

We aren't ready to show it off quite yet but we've been working on a new evolution of our eBrewing line. Using tech developed for SVBS and designed with today's homebrewer in mind, eBrewing 2.0 will bring exciting changes to our electric line up.

Featuring modular controllers that allow you to scale your system up or down easily, easy-to-use touch screen controls, and Brew in A Basket systems for compact footprints, eBrewing 2.0 will bring a lot to the table...or Brew Cube.

In the meantime, we are discounting our first generation of eBrewing gear to help make some room in the warehouse. eKettles, eControllers, RIMS, Systems, and eBrewing Accessories are marked down 30%. eBrewing Kits are discounted to reflect the same savings available on individual eBrewing products.

Designing every piece of our electric brewing equipment from scratch has enabled us to introduce a new level of process control, flexibility, and performance. Every detail has been carefully thought through and refined.

Designing every piece of our electric brewing equipment from scratch has enabled us to introduce a new level of process control, flexibility, and performance. Every detail has been carefully thought through and refined.

Primarily designed to be used with a brew in a bag system (BIAB), but can also be useful for someone who prefers modularity within their multi-vessel system. It can just as easily replace an existing propane fired HLT or Boil kettle as part of an existing 3 vessel brewhouse. The 1V controller is designed to operate one element, and is compatible with our line of 10 and 20 gallon eKettles. A 30A dedicated GFCI protected circuit is required.

Primarily designed to be used with a brew in a bag system (BIAB), but can also be useful for someone who prefers modularity within their multi-vessel system. It can just as easily replace an existing propane fired HLT or Boil kettle as part of an existing 3 vessel brewhouse. The 1V controller is designed to operate one element, and is compatible with our line of 10 and 20 gallon eKettles. A 30A dedicated GFCI protected circuit is required.

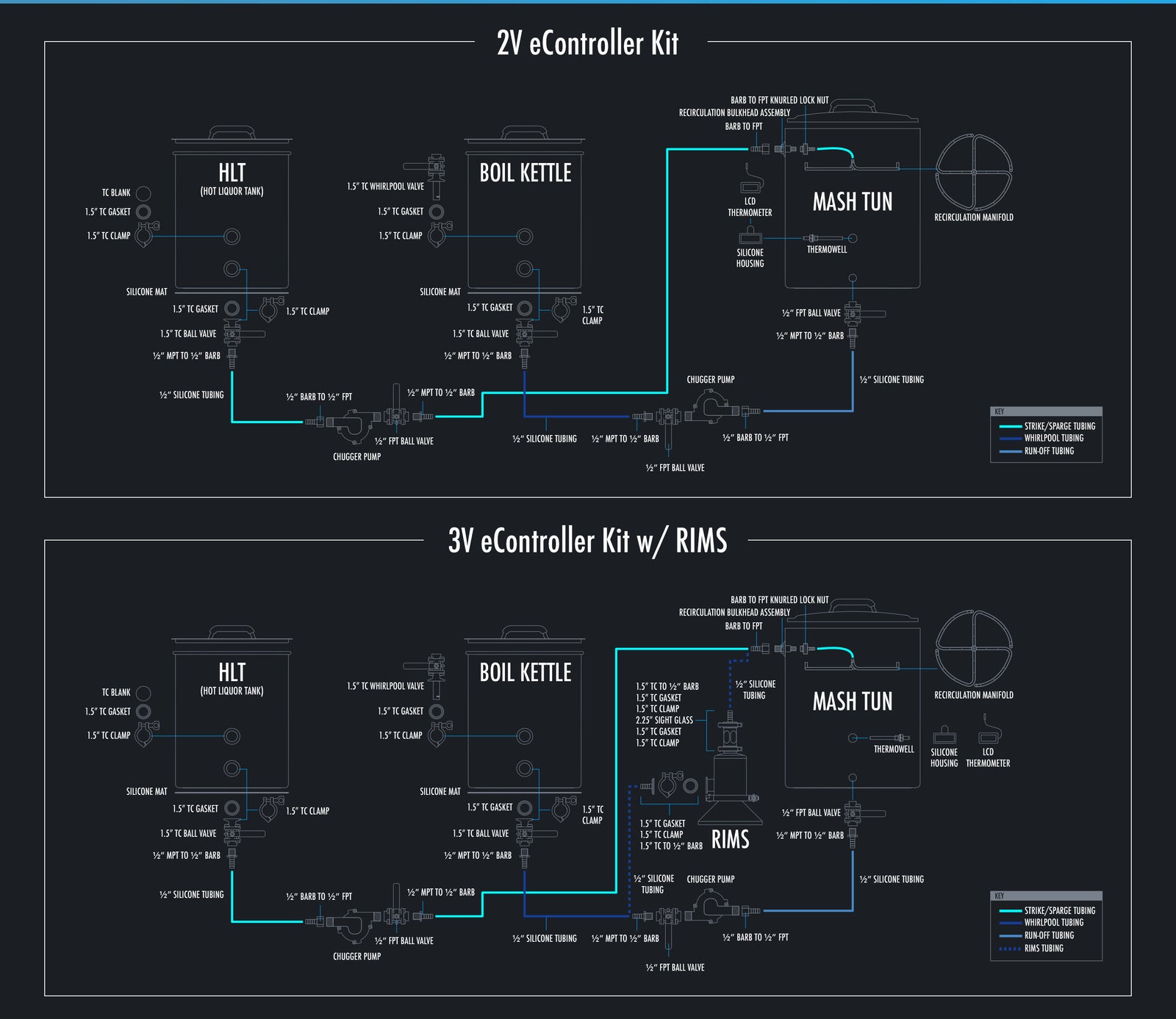

Designed to be used as part of a 3 vessel, single infusion mash system. The controller pairs perfectly with our line of insulated InfuSsion Mash Tuns, alongside a pair of traditional temperature controlled eKettles for the HLT and Boil Kettle. The 2V controller can operate 2 elements in total, albeit one at a time, and is compatible with our line of 10 and 20 gallon eKettles. Since only one element can be operated at a time, the 2V controller retains the same 30A GFCI protected circuit power requirement as the 1V.

Designed to be used as part of a 3 vessel, single infusion mash system. The controller pairs perfectly with our line of insulated InfuSsion Mash Tuns, alongside a pair of traditional temperature controlled eKettles for the HLT and Boil Kettle. The 2V controller can operate 2 elements in total, albeit one at a time, and is compatible with our line of 10 and 20 gallon eKettles. Since only one element can be operated at a time, the 2V controller retains the same 30A GFCI protected circuit power requirement as the 1V.

Designed to be used with a recirculating infusion mash system (RIMS). The 3V controllers is engineered to be used with a traditional 3 vessel, multi-step mash system, where each vessel can be temperature controlled. The 3V controller is designed to operate 3 elements in total, albeit 2 at a time, and will be compatible with our 10 and 20 gallon eKettles. As a result of the increased load of running 2 elements simultaneously, the 3V controller will require two discrete 30A GFCI protected circuits.

Designed to be used with a recirculating infusion mash system (RIMS). The 3V controllers is engineered to be used with a traditional 3 vessel, multi-step mash system, where each vessel can be temperature controlled. The 3V controller is designed to operate 3 elements in total, albeit 2 at a time, and will be compatible with our 10 and 20 gallon eKettles. As a result of the increased load of running 2 elements simultaneously, the 3V controller will require two discrete 30A GFCI protected circuits.

Our Recirculating InfuSsion Mash System (RIMS) features a 3500w Incoloy 800 helical element with a thermoprobe integrated into the base which is designed to read wort temperature as it leaves the RIMS housing. When used with an InfuSsion Mash Tun, the system is designed to provide the brewer the temperature gradient between mash and recirculating wort, allowing the perfect pump speed to be dialed in.

When used with an Ss Brewtech eController, the RIMs element can be fully modulated, which can prevent scorching and provide another layer of heat input and control. The RIMS kit includes a fully welded housing with TC connections, silicone base, and neoprene insulating jacket. For stabilization and control in a multi-step mash process there is simply not a better system on the market. Engineering Better Beer.

Our Recirculating InfuSsion Mash System (RIMS) features a 3500w Incoloy 800 helical element with a thermoprobe integrated into the base which is designed to read wort temperature as it leaves the RIMS housing. When used with an InfuSsion Mash Tun, the system is designed to provide the brewer the temperature gradient between mash and recirculating wort, allowing the perfect pump speed to be dialed in.

When used with an Ss Brewtech eController, the RIMs element can be fully modulated, which can prevent scorching and provide another layer of heat input and control. The RIMS kit includes a fully welded housing with TC connections, silicone base, and neoprene insulating jacket. For stabilization and control in a multi-step mash process there is simply not a better system on the market. Engineering Better Beer.

The eKettle was purpose-built for electric brewing and features 100% welded TC fittings, etched volume markings, and a new version of our popular trub dam. 1.5” TC service ports for the ball valve and accessories, along with a 2” TC dedicated element port with proprietary element locknut system. Aesthetically, the eKettle features front to back silicone overmolded handle orientation for a more compact brewhouse layout.

The eKettle was purpose-built for electric brewing and features 100% welded TC fittings, etched volume markings, and a new version of our popular trub dam. 1.5” TC service ports for the ball valve and accessories, along with a 2” TC dedicated element port with proprietary element locknut system. Aesthetically, the eKettle features front to back silicone overmolded handle orientation for a more compact brewhouse layout.

All 304 Stainless eKettle with Fully welded TC Fittings

1.5" TC ball valve port with trub dam

1.5" TC accessory port

2" TC element port with proprietary element locknut system

5500 Watt Incoloy 800 alloy Halo heating element

Integrated PT100 temperature probe

L6-30 connector molded into element base

All 304 Stainless eKettle with Fully welded TC Fittings

1.5" TC ball valve port with trub dam

1.5" TC accessory port

2" TC element port with proprietary element locknut system

5500 Watt Incoloy 800 alloy Halo heating element

Integrated PT100 temperature probe

L6-30 connector molded into element base